Food & Beverage Separation & Treatment Solutions

Purifying and treating our clients water and the manufactured products is our passion.

At the forefront of our clients challenges will be having compliant water for use in manufacturing, asset protection or CIP. The manufactured products will also require treatment or filtration to remove impurities and retain valuable characteristics. Fulfilling these challenges whilst operating the plant efficiently with as little waste and downtime is a delicate balance.

Product Quality

Maintaining consistent product quality requires precise control over parameters and filtration processes. Variations in process quality can significantly impact taste, appearance, and shelf life, making reliable treatment systems essential for brand consistency. Keeping sterility is also an enormous challenge factoring in many site specific factors that usually require a combination of filtration and a form of disinfection to keep balance.

Resource Optimisation

Water and energy usage is a significant item on every clients agenda with impacts ranging from production costs and environmental footprint to utilities costs and unnecessary discharge or waste products. Effective system design and management are essential for optimising resource consumption while maintaining product quality.

Food Safety Compliance

Food and beverage manufacturers must meet rigorous safety standards and regulatory requirements. Ensuring compliance while maintaining production efficiency requires careful management of process treatment processes and documentation.

Production Efficiency

Manufacturing schedules demand reliable, continuous operation of process treatment systems. Downtime can lead to significant production losses and increased operational costs, making system reliability crucial for operational success.

Solutions that safeguard critical water supplies, process manufactured products and factor in re-use of wastewater and undesirable products inline with our clients constant production and environmental targets.

End to End Solutions

We work closely with each manufacturer to develop water treatment strategies that match their specific production requirements and quality standards. Our approach ensures seamless integration with existing processes while maximising efficiency and product consistency.

Turnkey Project Capabilities with an end to end solution

CIP integrations and addition

Design and projection using specialist software

Current plant independent performance evaluation

Technology Selection

Carefully evaluation and implement of the most appropriate technologies for each unique production environment and application. Our expertise ensures optimal system performance whilst driving consistent, high-quality results for every product type.

Process generation and distribution of Chlorine Dioxide, Hydrogen Peroxide and Sodium Hypochlorite

Ion Exchange for use on river, borehole and municipal supplies with numerous application

High Efficiency Softening and De-aerated water using the Dyna-SAVE & Dyna-SEP Range

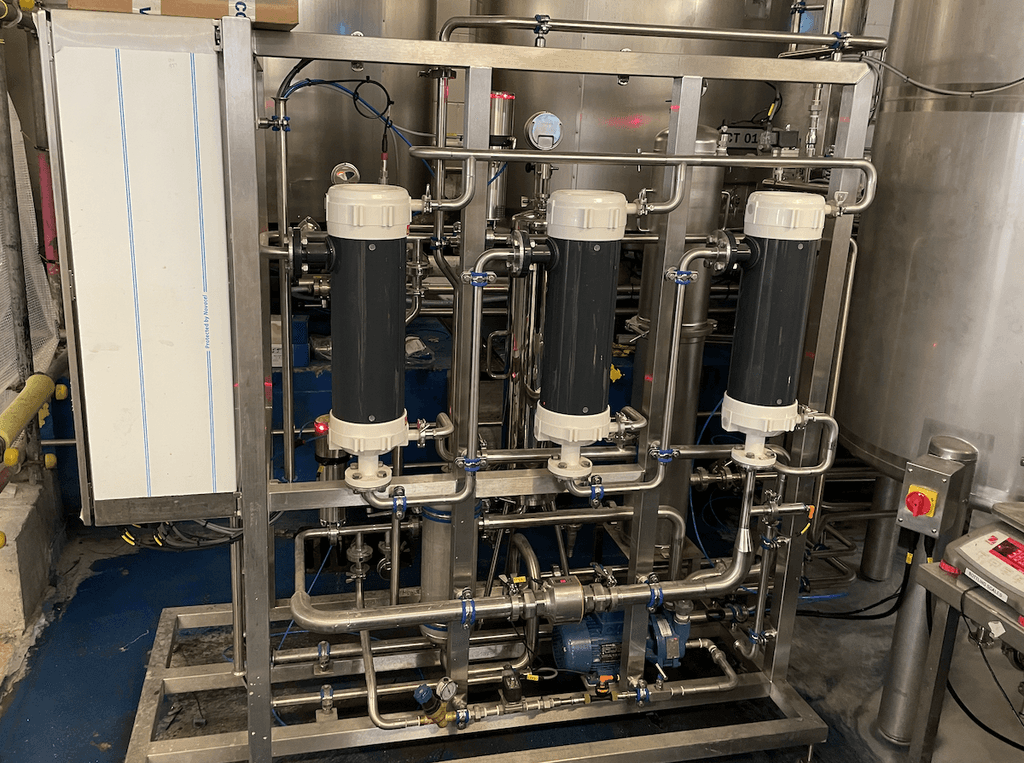

Automated filtration using Reverse Osmosis, Nanofiltration, Ultrafiltration and Microfiltration separation technologies

Lees Recovery for extracting further product from Lees and Tank Bottoms

Cartridge filtration for limitless applications to suit liquids and gases

Quality Management

Implement action of a robust monitoring and control protocols to maintain consistent water quality throughout your production processes.

Instrumentation calibration

Water quality sampling and independent lab analysis

Membrane and ion exchange analysis & autopsy

Performance tracking and review

Quality control programmes

Operational Support

Providing dedicated technical assistance and maintenance support to ensure your systems operate at peak efficiency. Our responsive team delivers proactive maintenance and rapid problem resolution while minimising impact on production schedules.

Planned maintenance

Online and remote support

Training and familiarisation for sites engineering team

Consultation

Reduced labour, material and consumables costs

Preferential callout response to issues with plant

Contact our experts today to discuss your requirements and discover how we can help improve your production processes.

Get in touch