Industry-leading membrane filtration technology delivering consistent particle removal down to 0.01 microns, ensuring product quality and process efficiency across multiple industries.

What is Ultrafiltration & Microfiltration?

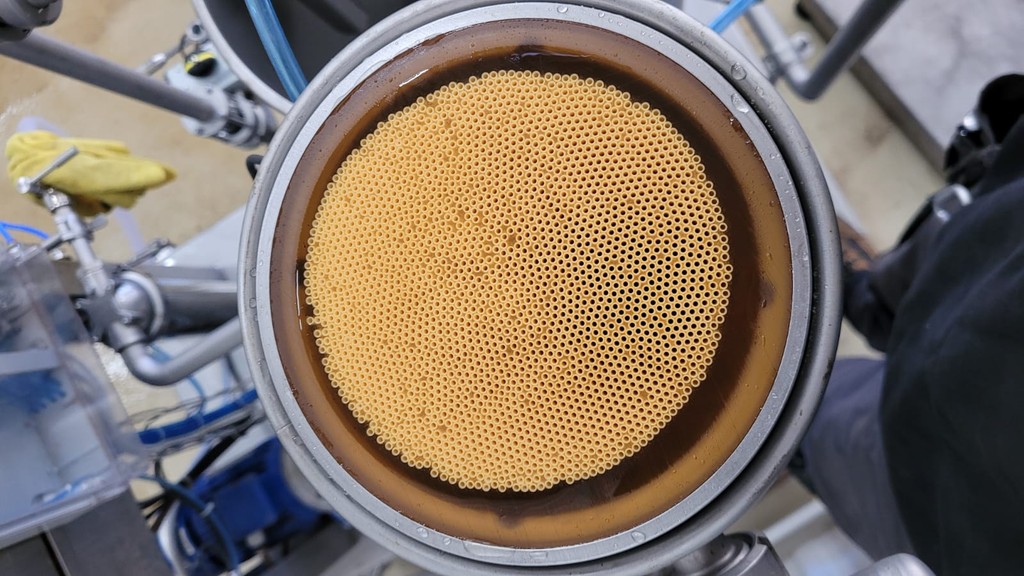

Microfiltration (MF) and Ultrafiltration (UF) are membrane filtration products that usually utilise hollow fibre modules.

MF uses membranes with pore sizes from 0.1 to 10 micrometers and operates at low pressures (0.1-2 bar) to remove suspended solids, bacteria, and larger microorganisms through simple sieving. UF represents a finer level of filtration, utilising membranes with pore sizes between 0.001 and 0.1 micrometers (1-100 nanometers) to capture smaller particles including proteins, viruses, and endotoxins through both size exclusion and surface interactions between the membrane and particles.

At Dynamic Water Solutions, our decades of experience in mastering these technologies encompasses both theoretical principles and practical implementation, allowing us to provide exceptional services that maximise membrane life and minimise operational costs across diverse industrial settings.

How to Successfully Build a Membrane Filtration System

Once we've established a design and selected the appropriate technologies, we will then decide in which configuration to operate them. When choosing UF and MF we have the flexibility to operate them in either dead end or crossflow configurations. These configurations are driven by what feed characteristics are to be filtered and the operating parameters within the design.

Cross-Flow Configuration

Maximum Efficiency for Challenging Applications

Cross-flow filtration directs the feed stream parallel to the membrane surface while maintaining constant pressure. This creates two output streams: a clean permeate that passes through the membrane and a concentrate containing rejected particles. The continuous flow across the membrane surface naturally prevents particle accumulation, making this configuration ideal for fluids with higher solids content or when consistent long-term performance is crucial.

While requiring additional energy for recirculation, cross-flow systems typically achieve longer operational cycles between cleaning and higher overall recovery rates.

Dead-End Configuration

Simplicity for Lower Solids Applications

In dead-end filtration, the entire feed stream flows perpendicular to the membrane surface, forcing all particles larger than the pore size to accumulate on the membrane. This straightforward approach requires less energy and simpler system design, making it cost-effective for fluids with lower solids content.

Regular automated cleaning removes accumulated particles, though cleaning cycles may be more frequent than in cross-flow systems. Dead-end configuration is particularly effective in drinking water applications and pre-treatment systems where simplicity and energy efficiency are priorities

Operational Benefits of Membrane Filtration

Modern membrane filtration systems represent a significant advancement in water treatment technology, offering substantial operational and economic advantages over traditional filtration methods.

By implementing either ultrafiltration or microfiltration systems, organisations can transform their fluid treatment processes while achieving significant cost savings and quality improvements.

Exceptional product qualities below 1 NTU

Minimal chemical requirements with automated cleaning vs filtration methods that require offline CIP

Lower energy costs with a professional design, commissioning and service plan

Longer equipment life and superior consumables lifespan against other filtration methods

High recovery rates and opportunities for reuse

Applications Across Industries

Membrane filtration technologies have revolutionised water treatment across multiple sectors, each with unique requirements and quality standards. Our expertise in both ultrafiltration and microfiltration enables us to deliver tailored solutions that meet specific industry challenges, from ensuring product quality in beverage production to maintaining sterile conditions in pharmaceutical manufacturing.

Industrial & Commercial Applications

In industrial settings, membrane systems provide essential filtration:

Process water treatment

Wastewater recovery

Cooling water filtration

Pre-treatment for high-purity water systems

Metal working fluid filtration

Closed loop filtration of any kind

Learn more

Food & Beverage Applications

Crossflow filtration systems play a crucial role in food and beverage production:

Water purification (Cryptosporidium and Suspended Solids Removal)

Beverage clarification

Wine and beer stabilisation

Vinegar clarification

Production and wastewater recovery

Learn more

Additional Services We Support

When your microfiltration or ultrafiltration requires troubleshooting Dynamic water solutions offers the full service package to include:

Process data normalisation and trend analysis

Onsite support and CIP

Off-site CIP and membrane autopsy

Module and component replacement

Instrumentation calibration

Learn more

Expert System Design & Implementation Process

At Dynamic Water Solutions, we understand that successful membrane filtration starts with meticulous system design and professional implementation. Our engineering-led approach combines decades of practical experience with the latest membrane technology developments, ensuring each system is optimised for its specific application.

From initial consultation through to final commissioning, we follow a proven methodology that minimises installation risks while maximising long-term operational benefits.

Design Considerations

Feed product quality analysis

Process requirements assessment

Space and infrastructure evaluation

Future capacity planning

Energy efficiency optimisation

Maintenance accessibility

CIP water & strategy assessment

Implementation Process

Detailed site surveys

Process integration planning

Installation coordination

System commissioning

Operator training

Performance verification

Why Partner With Dynamic Water Solutions?

Our membrane filtration heritage spans decades of innovation and practical application across multiple industries. Our understanding of both UF and MF principles allow us to provide a tailored approach to all products and surrounding services to exceed our clients expectations: