Membrane separation technology delivering exceptional ionic removal and concentrated separation, ensuring superior product quality and process efficiency across multiple industries.

What is Osmosis and Reverse Osmosis?

To understand reverse osmosis we need to define what osmosis is as a natural principle.

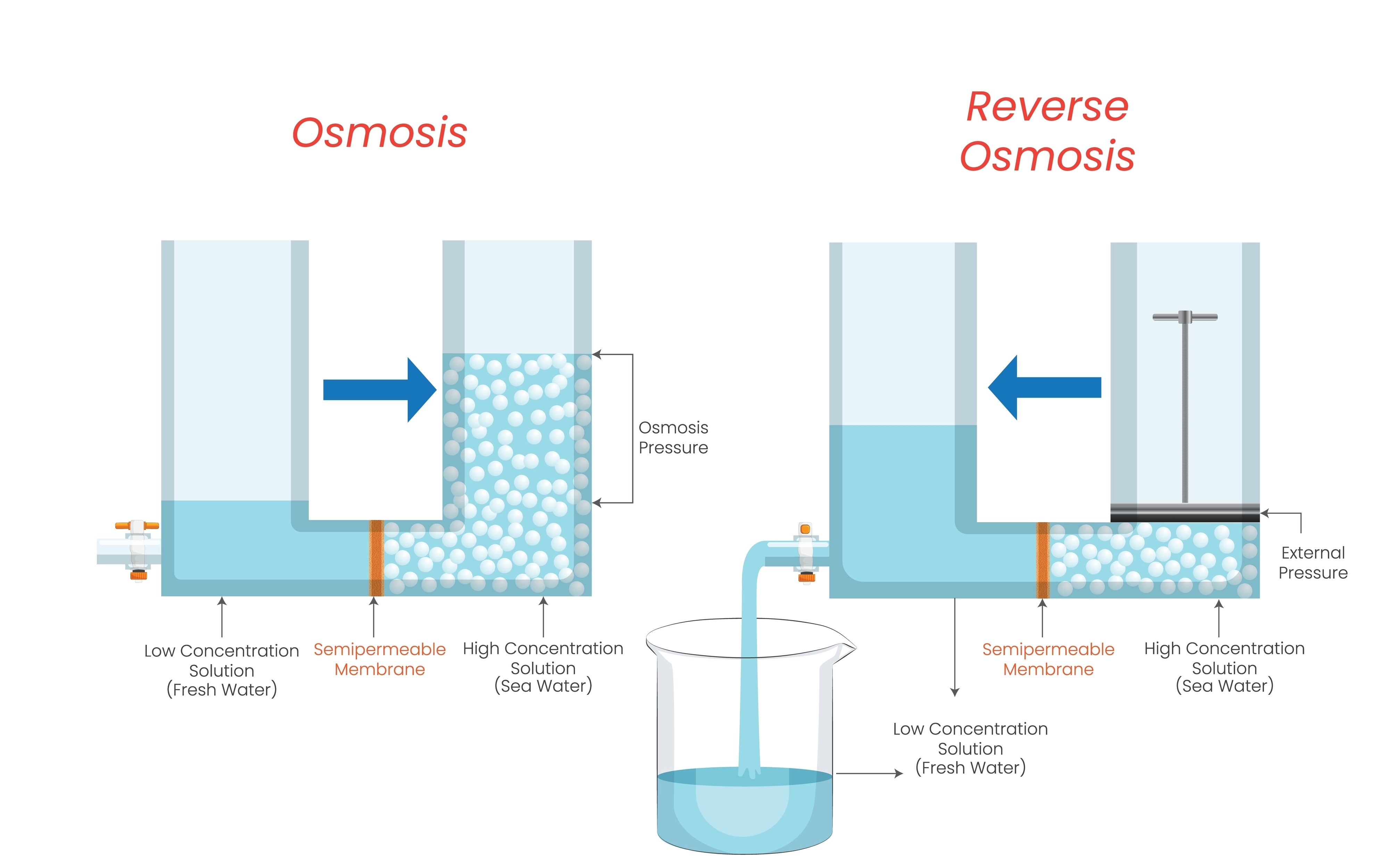

Osmosis is a natural process where molecules move through a semipermeable membrane from an area of higher water concentration to an area of lower water concentration. Imagine two solutions separated by a membrane - pure water on one side and salty water on the other. The molecules will naturally flow toward the salty side to try to equalise the concentration, causing that side to increase in volume.

Reverse osmosis (RO) is essentially forcing this natural process backward by applying pressure. In RO systems, pressure is used to push water through a semipermeable membrane, leaving contaminants behind. The membrane has tiny pores that allow water molecules through but block larger molecules like dissolved salts, bacteria, and other impurities.

Some common applications:

Purification and desalination plants use reverse osmosis to produce drinking water from seawater or brackish water.

Concentration of desirable materials using plant in combination with other technologies such as wastewater, beverage and dairy processing.

Wastewater recovery to reduce water discharge and reuse the permeate water for other uses at the facility.

What Membrane Technology is Required for Reverse Osmosis & Nanofiltration?

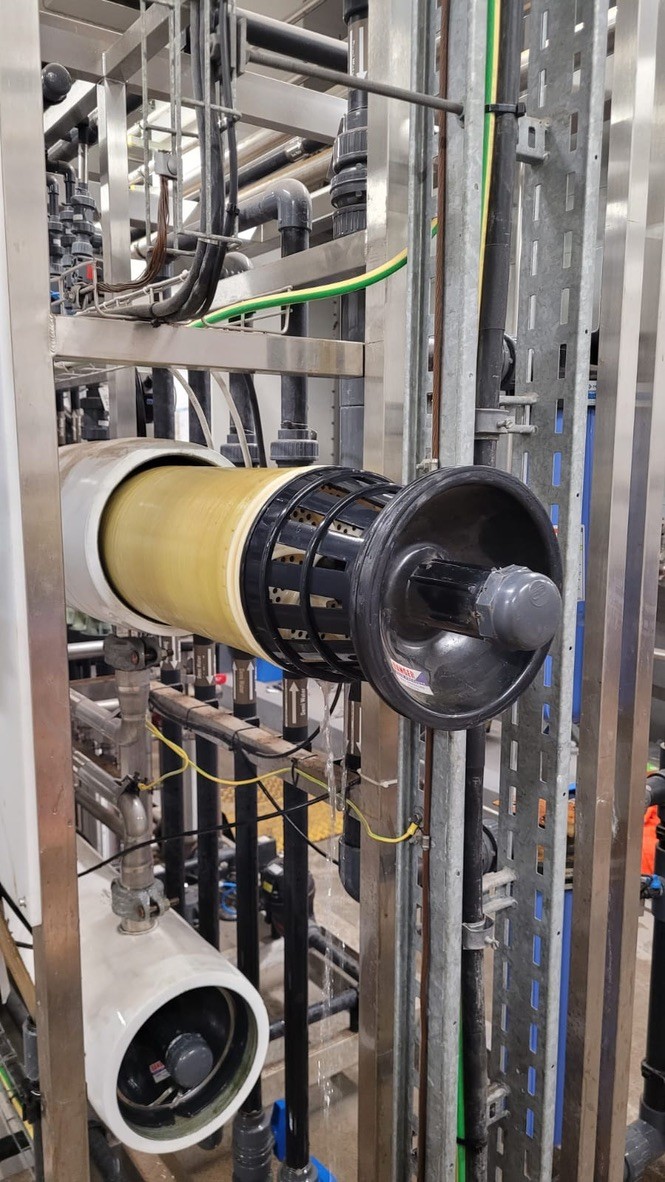

Reverse Osmosis (RO) and Nanofiltration (NF) are advanced membrane technologies operating at molecular level for superior separation in water treatment applications.

RO uses semi-permeable membranes (pore size ≤0.001 micrometers) at high pressures (up to 70 bar) to remove dissolved solids and produce ultra-pure water. NF operates at lower pressures (5-20 bar) to selectively remove multivalent ions whilst allowing specific monovalent ions to pass through, making it ideal for targeted separation requirements.

At Dynamic Water Solutions, we combine theoretical expertise with practical implementation to maximise membrane life and minimise operational costs across diverse industrial applications.

How to Successfully Build an RO/NF System

When designing RO and NF systems, careful consideration of feed quality and required product specifications is essential. Our approach focuses on optimising system configuration and operational parameters to achieve consistent, reliable performance.

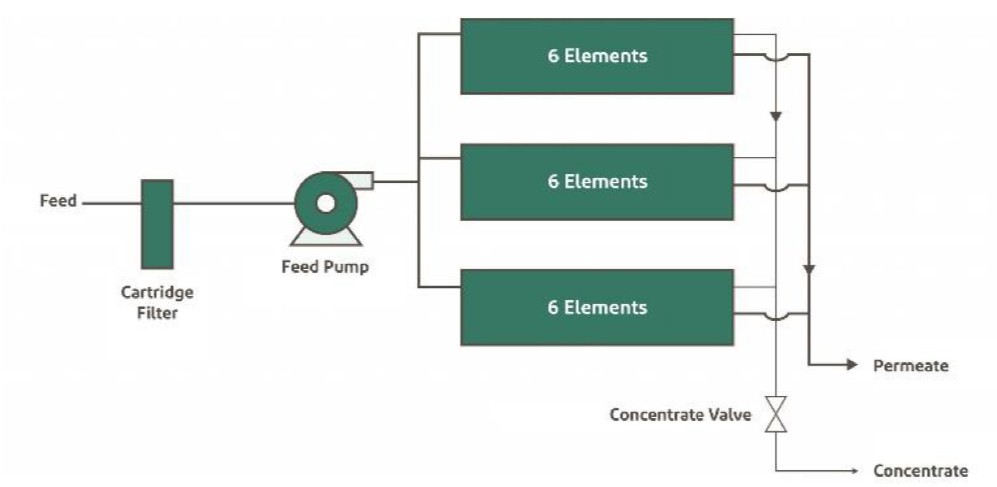

Single-Pass Systems

Ideal for Standard Applications Single-pass systems represent the most straightforward configuration, where feed water passes through the membrane array once. This configuration is suitable for applications requiring moderate purity levels and offers:

Simplified system design and operation

Lower capital investment

Reduced energy consumption

Easier maintenance procedures

Suitable for most commercial applications

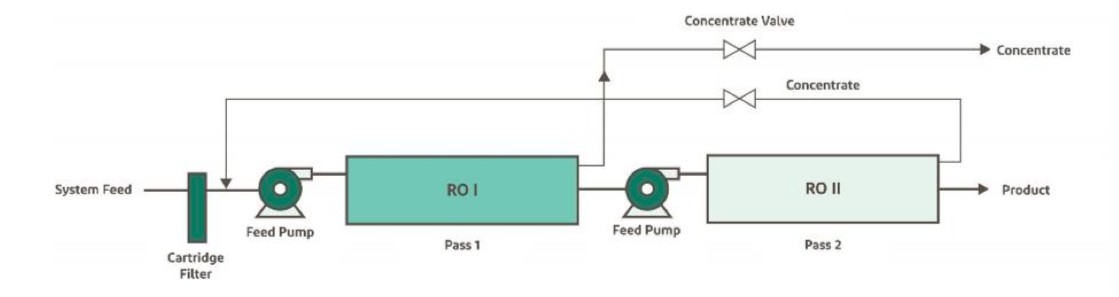

Double-Pass / Permeate Staged Systems

Maximum Purity for Critical Applications Double-pass systems direct the permeate from the first pass through a second membrane array, achieving exceptionally high purity levels. This configuration is essential for:

Ultra-pure water production

Pharmaceutical applications

Microelectronics manufacturing

Critical process water requirements

Applications requiring consistent sub-1 µS/cm conductivity

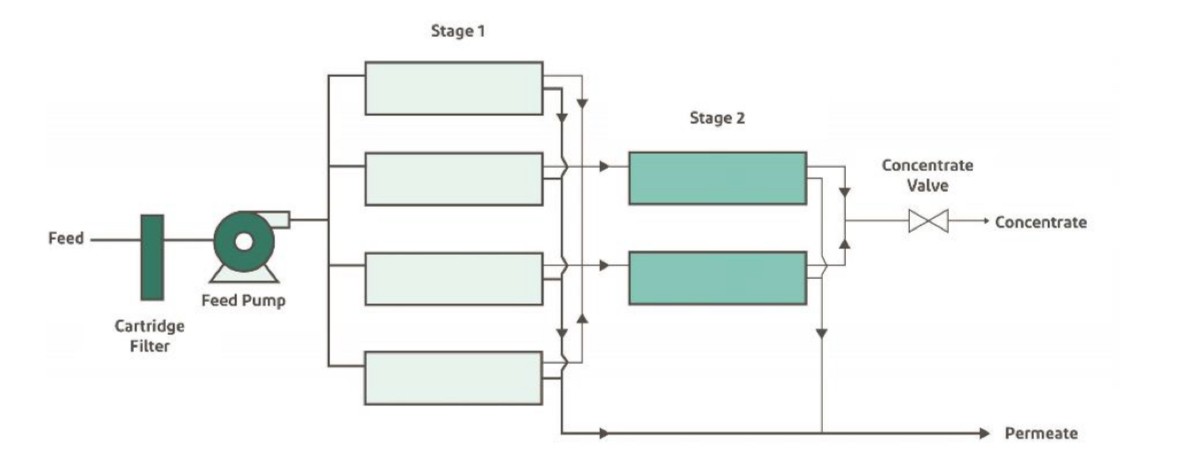

Multi Stage Systems

To get the most out a RO/NF Plant a design can incorporate additional stages to extract more product from the feedstock or concentrate feed characteristics even further to:

Recover more within the plant design and increase permeate capacity

Concentrate desirable or undesirable feed characteristics

Balance the entire design characteristics

Provide flexibility across the design

System Design Additions

Some designs will require or have a desire for additional options to promote greater efficiency and automation. One or a combination of the below will promote less use of resources such as water and power:

Permeate Blend

Interstage Boosting / Twin Technology Coupling (NF / RO)

High Efficiency Add ons - Concentrate Recirculation / Batch Recycle

Integrated CIP

18mOhm Water - EDI of Mixed Bed / Deaeration Module integration

Operational Benefits of RO/NF Systems

Modern RO and NF systems offer substantial operational advantages over traditional ion exchange and chemical treatment methods. By leveraging precise membrane separation technology, these systems deliver consistent, measurable results whilst significantly reducing chemical consumption and waste generation:

Exceptional ionic removal capabilities

Continuous operation with minimal downtime

Reduced chemical consumption

Lower operational costs

Consistent product quality

Automated in nature

Environmental sustainability against regeneration chemistry

Applications Across Industries

RO and NF technologies serve critical roles across multiple sectors, each with unique requirements and quality standards. Our expertise enables us to deliver tailored solutions that meet specific industry challenges.

Industrial & Commercial Applications

In industrial settings, RO/NF systems provide essential treatment:

Boiler feed water preparation

Cooling tower makeup water

Process water purification

Wastewater recovery and reuse

Pre-treatment for ultrapure water systems

Zero Liquid Discharge (ZLD) applications

Learn more

Food & Beverage Applications

RO/NF systems play crucial roles in food and beverage production:

Product water purification

CIP water for product interface

Concentrate recovery

Wine imperfection stabilisation

Juice concentration

Sugar refining

Mineral water production

Learn more

Expert System Design & Implementation Process

At Dynamic Water Solutions, our engineering-led approach combines decades of practical experience with the latest membrane technology developments, ensuring each system is optimised for its specific application.

Design Considerations

Feed water analysis

Product quality requirements

Recovery rate optimisation

Energy consumption analysis

Pre-treatment requirements

Post-treatment needs

Chemical cleaning strategy

Membrane selection criteria

Ongoing service and maintenance

Implementation Process

Detailed site surveys

Process integration planning

Installation coordination

System commissioning

Operator training

Performance verification

Maintenance planning

Why Partner With Dynamic Water Solutions?

Our membrane separation expertise spans decades of innovation and practical application across multiple industries: